Comprehensive Knowledge of Thermal Conductive Materials:

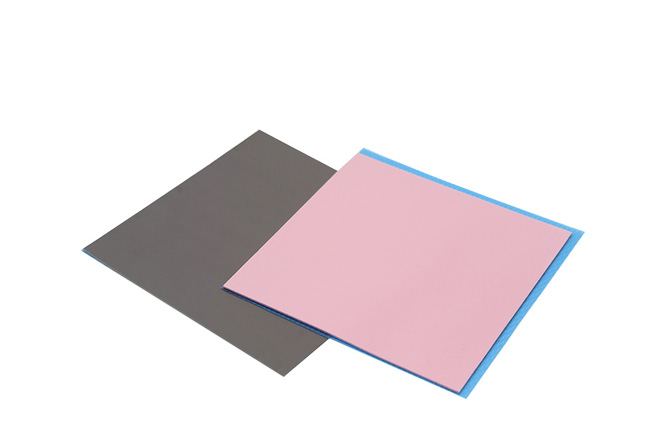

1. Composition of Thermal Conductive Silicone Pad:

- Polymerized Silicone Oil: Silicone Rubber (aging resistance, acid and alkali resistance, stable chemical properties, consistent service life with customer's equipment usage)

- Thermal Conductive Filler: Thermal Conductivity (Conduction efficiency) Molecular Thermal Motion (On IC and heat-generating body, it appears to be smooth, but actually is not smooth. The use of thermal conductive pads is aimed at expelling all the air out and filling the gap.)

- Flame Retardant Filler (1 Hydroxyl group, 2 Halogen, 3 Decabromobiphenyl Ether. Banned in July 2006)

- Crosslinking Agent (for connection)

- Adhesive (for bonding)

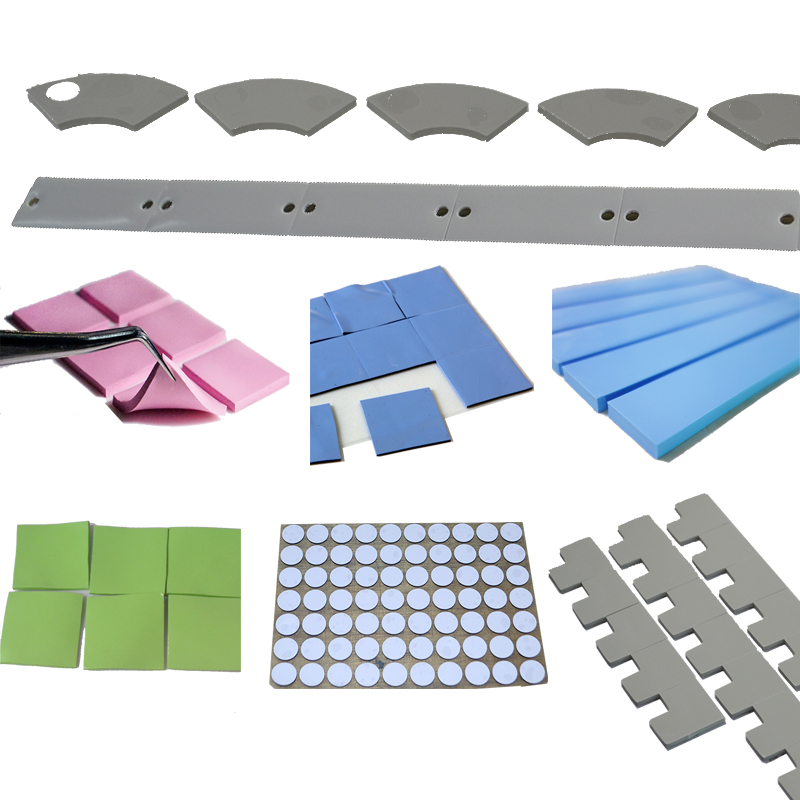

2. Characteristics:

- Excellent heat conduction ability

- Chemical stability and aging resistance, long service life

- Excellent electrical insulation properties (the ability to withstand high voltage increases proportionally with the increase in thickness with a linear relationship)

- Flame retardant ability

- Self-adhesive ability. If a back adhesive is added, customers should be informed that double-sided adhesive is easy to melt at high temperatures, air exists, and it does not have thermal conductivity, so the thermal conductivity will decrease

- Processability (cut and molding)

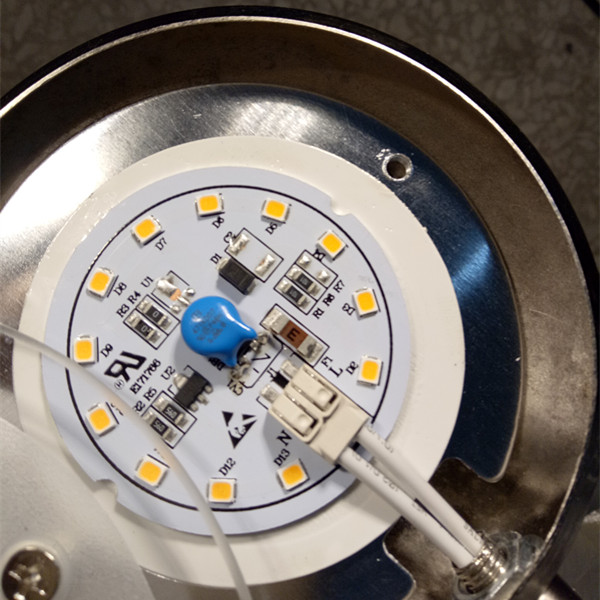

3. Application Scope:

- Transistors, chipsets, IC controllers

- Information processing (servers, workstations, communication base stations, LED, DVD, CD-ROM, laptops)

- Automobile control components (car LCD monitors, car audio, televisions)

- Consumer electronics products (plasma TVs, flat-screen TVs, mobile DVDs)

4. Parameters of Thermal Conductive Silicone Gel:

- Hardness: The ability of an object to resist external forces (ASTM D2240 test method for measuring rubber hardness with a durometer)

- Specific Gravity: Density/Water Density. The higher the density, the better the thermal conductivity.

- Weight Loss: Measured over 24 hours (180 degrees high temperature, continuous baking for 30 minutes)

- Elongation: Tensile Strength

- Thickness: Measured with a thickness gauge (ASTM D374)

- Breakdown Voltage: Continuos voltage breakdown voltage < instantaneous breakdown voltage, 4000V is only required in this industry.

- Flame Rating: (94-V0) UL (civilian organization, fire prevention, and insulation)

- Thermal Conductivity: If two parallel planes having the same area of 1cm² and separated by a distance of 1cm have a temperature difference of 1K between them, then the amount of heat transmitted within 1 second from one plane to the other is defined as the thermal conductivity of the substance.

Dobon firmly believes that quality is the soul of products, and strictly abides by every standard, every process of production, and every detail of service!

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.